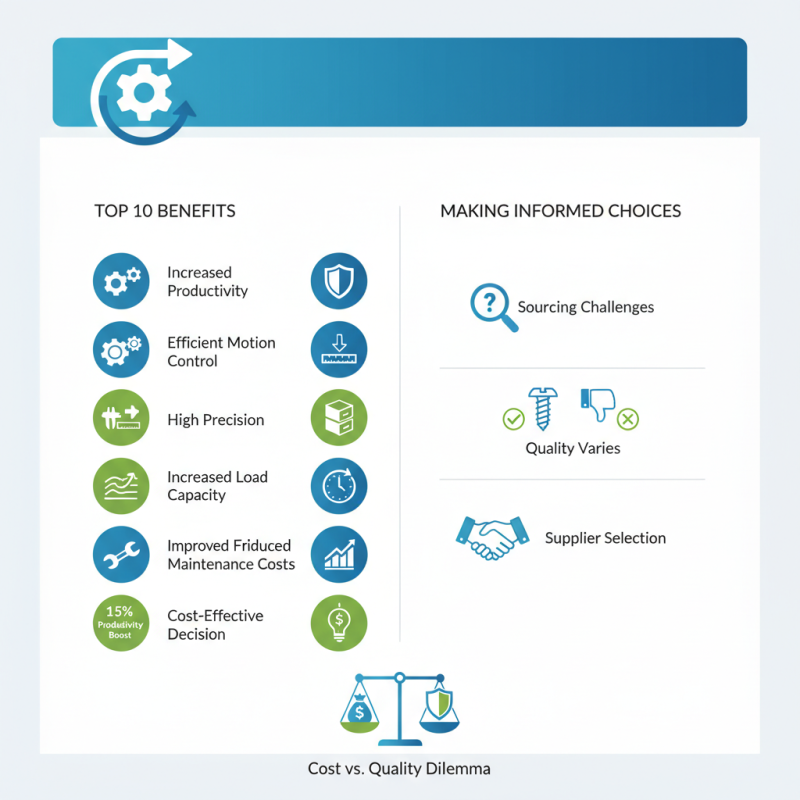

Top 10 Benefits of Using Ball Screws for Sale

In the competitive landscape of manufacturing, efficient motion control is crucial. Ball screws are an essential component in various machinery, providing high precision and durability. A recent industry report highlighted that using a "ball screw for sale" can significantly enhance operational efficiency by reducing friction and increasing load capacities. These screws, known for their reliability, contribute to improved cycle times and reduced maintenance costs.

Companies that utilize ball screws often report a 15% increase in productivity. However, sourcing the right ball screw can be challenging. Not all ball screws are designed equally; quality varies and influences performance. This brings attention to sourcing options in the market. Selecting the right supplier is critical to avoid long-term issues.

Understanding the benefits of using a ball screw for sale goes beyond just improved mechanics. It’s about making informed decisions that impact overall performance and productivity. While many celebrate these advantages, it’s worth reflecting on the implications of poor choices in suppliers and products. Balancing cost and quality remains a dilemma for many manufacturers.

Advantages of Ball Screws in Precision Motion Control Systems

Ball screws play a vital role in precision motion control systems. They convert rotational motion into linear motion with impressive accuracy. This feature is crucial for applications where every millimeter counts. Using ball screws can significantly improve positioning accuracy in machinery. Their design minimizes friction, providing smoother movements.

Tips: Always consider load requirements before selection. Overloading a ball screw can lead to premature failure. Regular maintenance is essential to maintain efficiency.

Another advantage is their high efficiency. Ball screws can achieve over 90% efficiency, reducing energy consumption. This is an important factor for manufacturers aiming to cut operating costs. However, improper installation might lead to complications. It's vital to follow guidelines carefully. A minor oversight can cause misalignment.

Additionally, ball screws have a long lifespan. They withstand heavy loads and cycling motions, making them durable. However, they require a proper lubrication strategy. Insufficient lubrication will lead to wear and can shorten their operational life. Attention to detail in these areas can optimize performance significantly.

Enhanced Load Capacity: Why Choose Ball Screws for Heavy Applications

When considering heavy applications, the load capacity is crucial. Ball screws excel in this area. They distribute weight evenly, allowing for better handling of substantial loads. This feature is vital in industries like manufacturing and aerospace. A well-designed ball screw can carry significant weights without compromising performance.

The construction of ball screws enhances their reliability. They consist of a screw shaft and ball bearings, which reduce friction. This friction reduction allows for smoother operation under heavy loads. However, improper installation can diminish these benefits. Users must ensure precise alignment during setup. Neglecting this can lead to uneven wear and tear on components.

Moreover, ball screws provide durability. They withstand stress over extended periods. But maintenance is essential for longevity. Regular inspections can prevent unexpected failures. Yet, some may overlook this step. Without diligent care, the benefits of enhanced load capacity may be lost. Taking responsibility in maintenance is key to maximizing performance.

Improved Efficiency: The Role of Ball Screws in Energy Savings

Ball screws are increasingly recognized for their role in improving efficiency. They convert rotary motion into linear motion with minimal friction. This design greatly reduces energy consumption in machinery. For instance, when compared to traditional lead screws, ball screws can often save up to 80% in energy costs. This is essential for industries looking to decrease operational expenses.

Moreover, ball screws enhance speed and accuracy. By providing smoother motion, they minimize the wear and tear on components. This durability leads to longer equipment lifespans and fewer replacements. However, it's important to acknowledge that they may require precise installation and alignment. Misalignment can negate their energy-saving benefits. Regular maintenance is crucial to maintain their optimal performance.

In real-world applications, organizations have enjoyed significant cost reductions. However, not every facility may realize these benefits immediately. Some companies may face challenges in integrating ball screws into existing systems. Understanding the initial investment versus long-term savings is vital. Every user must reflect on their unique situation before fully committing to this technology.

Top 10 Benefits of Using Ball Screws for Sale - Improved Efficiency

The following bar chart illustrates the top benefits of using ball screws, highlighting their impact on energy savings and overall efficiency in various applications.

Reduced Friction: How Ball Screws Minimize Wear and Tear

Ball screws offer unique advantages, particularly in reducing friction. This reduction minimizes wear and tear on machinery. With less friction, components last longer. Maintenance becomes less frequent. This translates to overall cost savings for businesses.

The design of ball screws includes ball bearings that travel along a screw shaft. This mechanism allows smooth motion. Because of this, energy is used more efficiently. Machines operate quieter as well. However, not all applications benefit equally. Poor alignment can lead to issues. Adjustments may be needed to achieve optimal performance.

Reducing friction has another layer of complexity. It not only prevents damage but can affect precision. In critical applications, even small deviations matter. Observing and adjusting workflows are crucial for success. Users must remain vigilant about potential risks. Continuous improvement in setup is key.

Top 10 Benefits of Using Ball Screws for Sale - Reduced Friction: How Ball Screws Minimize Wear and Tear

| Benefit | Description | Impact on Performance | Long-Term Advantages |

|---|---|---|---|

| Reduced Friction | Ball screws utilize rolling balls to minimize friction between moving parts. | Improved efficiency and smoother operation. | Less wear and tear, prolonging equipment life. |

| Higher Efficiency | Lower energy consumption compared to traditional lead screws. | Reduction in energy costs. | Sustainability in operations. |

| Precision Movement | Ball screws offer high positional accuracy. | Enhanced precision in applications. | Better quality of final product. |

| Load Capacity | Can handle high loads due to ball bearings. | Greater design flexibility. | Capable of supporting heavier machinery. |

| Versatile Applications | Used in various industries from robotics to aerospace. | Adaptable to numerous types of machinery. | Market competitiveness through innovation. |

| Reduced Maintenance | Longer service life needs less frequent maintenance. | Lower operational downtime. | Cost savings on maintenance and repairs. |

| Smooth Operation | Constant contact between balls ensures smooth motion. | Enhanced user experience and performance consistency. | Increased satisfaction from end-users. |

| Temperature Control | Better heat dissipation due to lower friction. | Reduced risk of overheating. | Enhances longevity of components. |

| Dynamic Rigidity | High rigidity helps maintain accuracy under load. | Stability during operation. | Consistency in production output. |

| Cost-Effectiveness | Lower total cost of ownership over time. | Budget-friendly implementation. | Better allocation of resources in business. |

Versatility of Ball Screws in Various Industrial Applications

Ball screws are critical components in many industrial applications. They convert rotary motion into linear motion efficiently. Their design allows for high precision and minimal friction. This makes them ideal for tasks requiring quick and accurate movements. Industries like robotics and aerospace rely heavily on them.

In manufacturing settings, ball screws are versatile. They can handle various loads and speeds. Their ability to maintain accuracy over extended periods is impressive. For instance, they are often used in CNC machines. The precise motion they provide enhances the overall productivity of the machines.

However, ball screws are not without challenges. They require proper maintenance to function effectively. Dust and debris can impact their performance. Users must ensure they are adequately lubricated. This maintenance can be a hassle and may be overlooked. It's essential to balance the benefits with potential drawbacks for optimal use.

Article Source:

Copyright © 2021 Payless Pet Products - All Rights Reserved.