2026 Best Butterfly Valves for Sale What to Consider?

In the rapidly evolving industrial landscape, choosing the right butterfly valves for sale is crucial. According to a recent report by ValvExpert, the global market for butterfly valves is projected to reach $4.5 billion by 2026. This indicates an increasing demand for reliable and efficient flow control systems. Industry expert Dr. Jane Smith emphasizes, “Investing in high-quality butterfly valves can enhance operational efficiency and reduce leakage.”

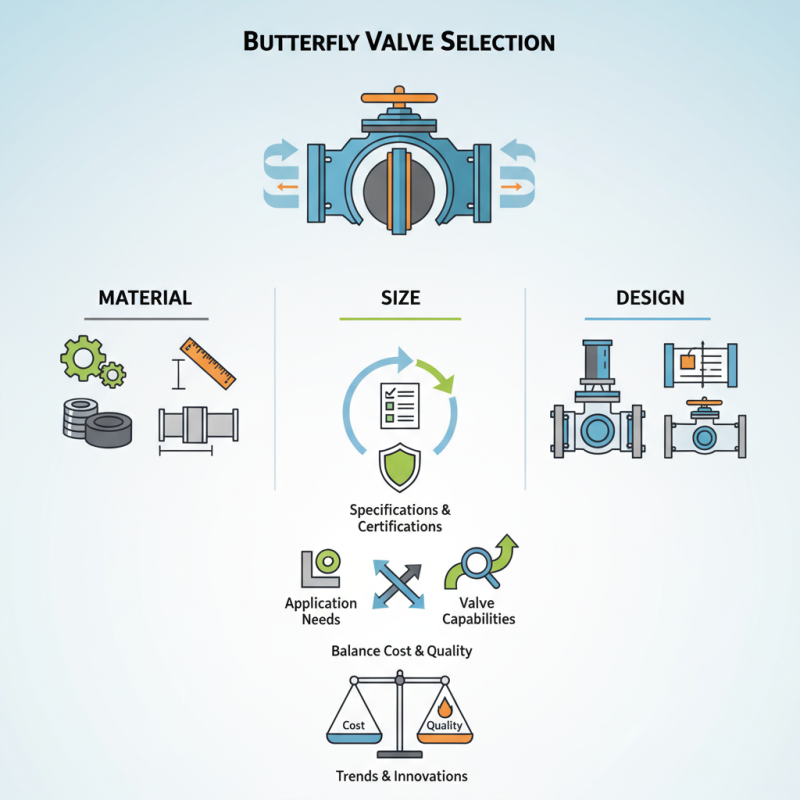

When selecting butterfly valves, several factors come into play. These include material, size, and design. Each factor can significantly impact performance and longevity. Understanding specifications and certifications is vital, as not all products in this space meet stringent industry standards. A perfect match between application needs and valve capabilities is often overlooked.

Many users have reported frustration with valve performance under varying conditions. It's essential to reflect on past buying decisions to avoid similar mistakes. Striking the right balance between cost and quality can be challenging. Evaluating options thoroughly will lead to an informed decision. As the industry advances, staying updated on trends and innovations in butterfly valves for sale is more important than ever.

Overview of Butterfly Valves and Their Applications

Butterfly valves are essential components in various industrial applications. They regulate fluid flow with minimal resistance. Typically, these valves are installed in piping systems, including water distribution, wastewater treatment, and chemical processing. According to a recent industry report, the global butterfly valve market is projected to reach $8.6 billion by 2027, driven by infrastructure growth and increasing demand for efficient fluid management.

When selecting a butterfly valve, consider material and size carefully. Common materials include stainless steel and PVC, each offering unique advantages. The appropriate size is crucial for optimal performance. A mismatch can lead to inefficiencies or failures, which can be costly. Take time to assess operational conditions such as temperature and pressure, as they significantly influence valve longevity and effectiveness.

**Tip:** Always consult technical specifications. It is vital to ensure compatibility with your system. For long-term durability, regular maintenance is necessary. Listen to feedback from operators. Unmet expectations may highlight underlying issues, prompting improvements. Investing time in proper selection and maintenance pays off in safety and performance.

Key Factors to Consider When Purchasing Butterfly Valves

When purchasing butterfly valves, several key factors should be considered. First, the valve's material plays a crucial role in its performance. Common materials include cast iron, stainless steel, and PVC. Each material has its own strengths and weaknesses. For instance, stainless steel offers excellent corrosion resistance, while PVC is more cost-effective for less demanding applications.

Another important factor is the valve's size and pressure rating. According to industry reports, more than 40% of valve failures stem from improper sizing. It’s vital to ensure the valve matches the pipeline specifications. Proper sizing directly influences flow efficiency and operational reliability.

Tips: Always refer to the manufacturer’s specifications. Measure your pipeline accurately. Check the pressure requirements for your specific application.

Another aspect to consider is the type of seal used in the valve design. A tight seal prevents leaks, which can lead to significant losses and equipment damage. Many reports indicate that leakages can cost facilities thousands of dollars annually. Consider valves with reliable sealing options that meet your operational needs.

Choosing the right actuator is also critical. A well-matched actuator ensures proper valve functioning. Mismatched actuators can lead to slower response times or operational failures. Always evaluate the actuator type relative to valve application conditions.

Types of Butterfly Valves Available in the Market

When exploring the types of butterfly valves available in the market, it's essential to consider various aspects. Two primary types are resilient seat and high-performance butterfly valves. Resilient seat valves are often used in water applications. They are economical and offer good sealing. However, they may not perform well under high-pressure conditions.

High-performance butterfly valves, on the other hand, are built for more demanding situations. These valves can handle high pressures and temperatures with ease. They are commonly made from durable materials, which enhances their longevity. But, their complexity can lead to higher maintenance costs.

Lastly, functionality isn't just about price. Select a valve that matches your requirements but also has a reputation for reliability. It's crucial to weigh both cost and quality carefully. Remember, choosing the wrong valve can result in inefficiencies or even dangerous situations in an operational environment.

Comparative Analysis of Top Brands for Butterfly Valves

When selecting the best butterfly valves for your needs, brand comparison is crucial. Various brands offer unique designs and features. Some specialize in high durability, while others focus on cost-effectiveness. Examine the materials used; stainless steel is often preferred for its strength. However, some may offer lighter options.

Tip: Always consider the valve's size and application. Ensure it fits your specific operation requirements. Not every brand excels in all categories. Some may have outstanding customer service but lack in performance or warranty.

It's also important to look at the installation process. Some brands might claim easy installation, yet users report complexities. Read reviews for real insights; glossy ads often miss the nuances. Understanding your specific needs will help you navigate through brand claims.

2026 Best Butterfly Valves Performance Comparison

Maintenance Tips for Longevity of Butterfly Valves

Maintaining butterfly valves is crucial for their longevity and performance. Regular checks can prevent unexpected failures. Inspect the valve body for corrosion and wear. Even small damages can lead to significant issues later on. Remember, a simple scratch can escalate into a bigger problem.

Lubrication is another essential aspect. Proper lubrication of the stem and seat significantly enhances performance. You may overlook this step, but it makes a difference. Neglecting it can lead to excessive friction and wear. This often results in reduced efficiency.

Cleaning is vital too. Remove any debris that might obstruct the valve's operation. Use a soft cloth for delicate areas. Harsh chemicals might cause more harm than good. If you notice unusual noises or leaks, address them immediately. Delaying repairs can lead to more extensive damage. The goal is to maintain optimal function without major overhauls. Regular maintenance pays off in the long run.

Article Source:

Copyright © 2021 Payless Pet Products - All Rights Reserved.